Pneumatic Pressure Control Valve, one of two basic guide plunger valve core, the floating sleeve compression type, from the seat structure, modular design, the flow capacity is big, high controlling precision, adjustable range, can achieve minimal flow control, structure is simple, reliable, good seal performance, the scene is easy to maintain. Is suitable for the pressure difference is not big, the seat leakage and high control precision.

More hydraulic control valve knowledge can be downloaded in PDF.

Product Description

Pneumatic pressure control valve is capable of regulating the system pressure to adjust the force on the hydraulic piston rod or the torque on the hydraulic motor shaft. Pressure relief valves are used to set the maximum pressure in the circuit and prevent it from being overloaded. Pneumatic pressure control valve permanently maintain the output pressure at the set value while preventing overloading of the equipment. Unloading valves are designed for economic pressure control in accumulator operating circuits and are used as a power source for emergency control.

In the pneumatic transmission system, all pressure control valves work on the principle of balance between air pressure and spring force, which can be divided into the following three categories:

1. Pressure reducing valve. Also known as pressure regulating valve, setting device (precision pressure reducing valve), etc., it plays the role of pressure reducing and stabilizing;

2. Overflow valve. Also known as safety valve, pressure-limiting shut-off valve, etc., it plays the role of pressure-limiting safety protection;

3. Sequence valve and balance valve. Depending on the pressure of the gas circuit, some control is performed.

Next, we mainly introduce you this single-seat cut-off pressure control valve.

Hydraulic pressure control valve has Long life

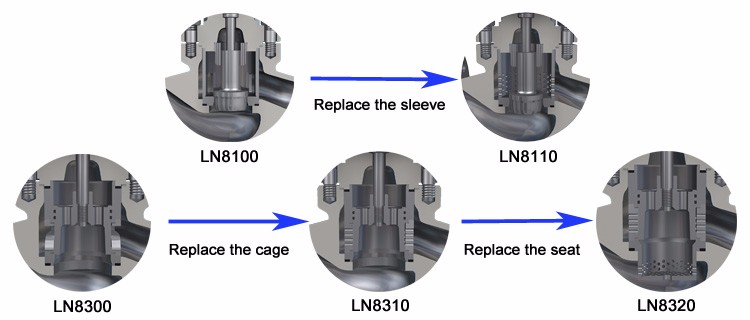

1. Single Seat Globe Control Valve Valve Trims

According to the needs of the working conditions, different materials and surface hardening treatment can easily be chosen to meet the requirements of each function module of trim to improve its performance of the corrosion, cavitation and erosion resistant, lengthen service life.

2. Pressure Control Valve body

The body of LN8 Single Seat Globe Valves consists of two passages from upper and lower, forming a shape like letter "S". The design of an elliptical section reduces the flow resistance and turbulent flow to keep the flow fluent. The flap in the middle of upper passage can reduce the eddy flow and increase the flow capacity.

3. Single Seat Globe Valve Actuator

The standard mate of Single Seat Globe Valves is AM8 Multi-spring pneumatic diaphragm actuator, which can be used in many conditions with the features of strong output force, high reliability, long lifespan and extensive applications. The output force changes with the number of springs. The high stress resistant diaphragm, bearing maximum pressure of 0.5 MPa air supply, gives globe valves a reliable shutoff. This type of actuator has a long life cycle with more than 1 million times.

We have been the leader in the valve industries, we have our own design and production system.

Test Items | National Standard | SUPCON Standard | Measured Results |

Seat Leakage | 0.06 L/min | 0.064 L/min | 0.01L/min |

Rated Travel Error | +2.5% | +2% | 1.32% |

Start Error | ±2.5% | ±2% | 0% |

End Error | ±2.5% | ±2% | 0.08% |

BasicError | ±1.5% | ±1% | -0.52% |

Hysteresis | 1.5% | 1% | 0.16% |

Dead Band | 0.6% | 0.4% | 0.38% |

Our company has a field experienced and strong technical team, and also committed to the development of stringent complex working condition control valve such as ball Valves and Globe Valves, to solve high pressure, corrosion, flash, erosion, large differential pressure and a series of technical problems. More knowledge can be downloaded in flow and directional control valve pdf.

Our company is committed to providing users with international competitiveness of high quality products and comprehensive technical services in oil and refinery, petrochemical, coal chemical, fine chemical, metallurgy and so on. We can help you provide solutions based on your actual situation!

Our company has been a leader in the valve industry, we guarantee delivery time and products quality! For more products menus and information, welcome customers to consult us.

For more related knowledge, click on the article below.

What Is Valve Cavitation? How to Eliminate?

A Brief Introduction to the Control Valve (Part 1)

A Brief Introduction to the Control Valve (Part 2)

TECHNICAL PARAMETERS

| Nominal Size | DN15 ~ DN300 |

| Pressure Rating | PN16/25/40/63/100;CL150(PN20)/300(PN50)/600(PN110) |

| Operateing Temperature | -196℃~ 593℃ |

| Characteristics | Equal percentage, linear, quickly open |

| Rangeability | 30:1、50:1、 100:1 |

| Seat Leakage Class | ANSI B16.104: IV、V、VI |

| Body Material | WCB/WCC/LCB/LCC;WC6/WC9;CF8/CF8M;4A/5A etc. |

| Trim Material | 630/316/316+ST/316nitriding/316+Ni60/316+WC etc. |

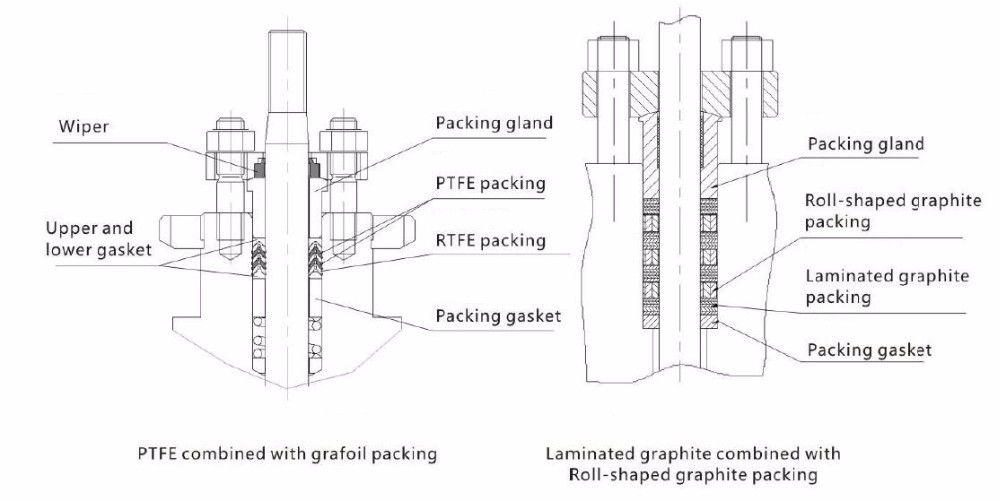

| Seal Material | PTFE+ graphite v-shaped packing, flexible graphite ring packing, graphite +PTFE braided packing etc. |

Headquarter Add.: SUPCON Park, No.309 Liuhe Road, Binjiang District, Hangzhou, 310053, China.

Tel.: +86 571 8111 9774

Fax: +86 571 8111 9737

E-mail: [email protected]