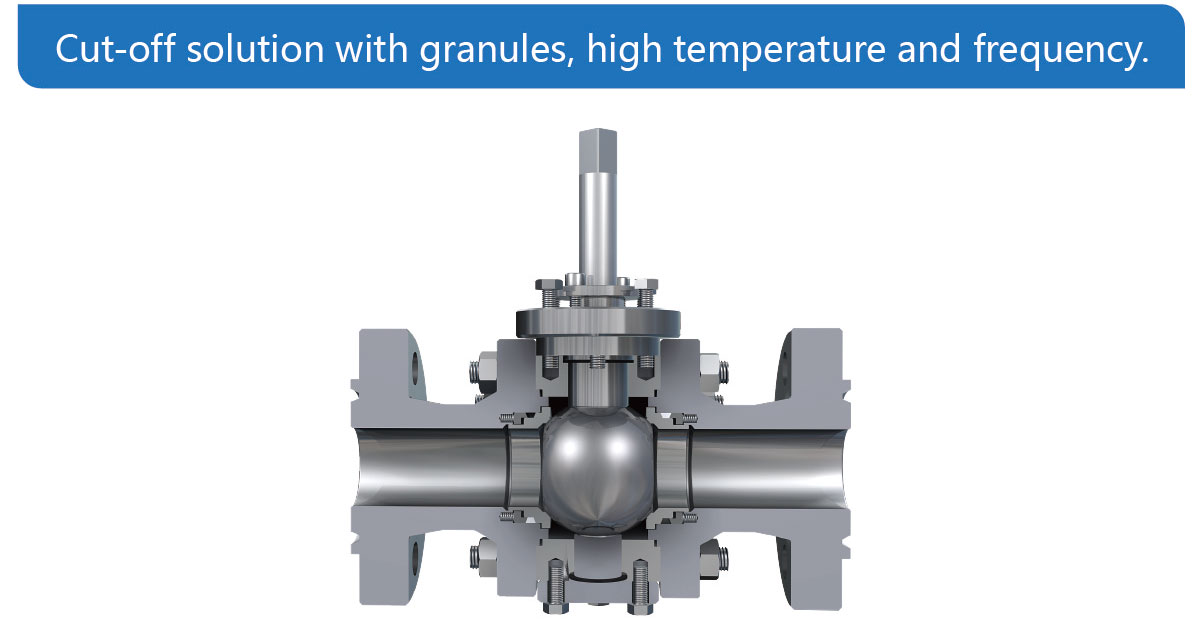

Sn53/54 series hard sealing O type ball valve is a full-size valve with excellent sealing performance, sensitive action without sticking, essential fire prevention and safe pressure relief in the middle chamber. It is suitable for fluid containing fixed particles and slurry at different temperatures and pressures.

Product Description

SN5 series hard seal ball valve is a full bore metal sealed ball valve, which was certified by API6D in 2017 and TÜV ISO15848, BV SIL3 in 2019. This type of ball valve is divided into two types: floating and fixed, with special material metal sealing sub-structure, excellent cut-off and sealing performance, low driving torque, smooth and reliable operation, which can be widely used in various process industries, automation control fields at different temperatures and pressures containing solid particles and slurry type fluids for tight cut-off control.

Adopting dewaxing precision casting process.

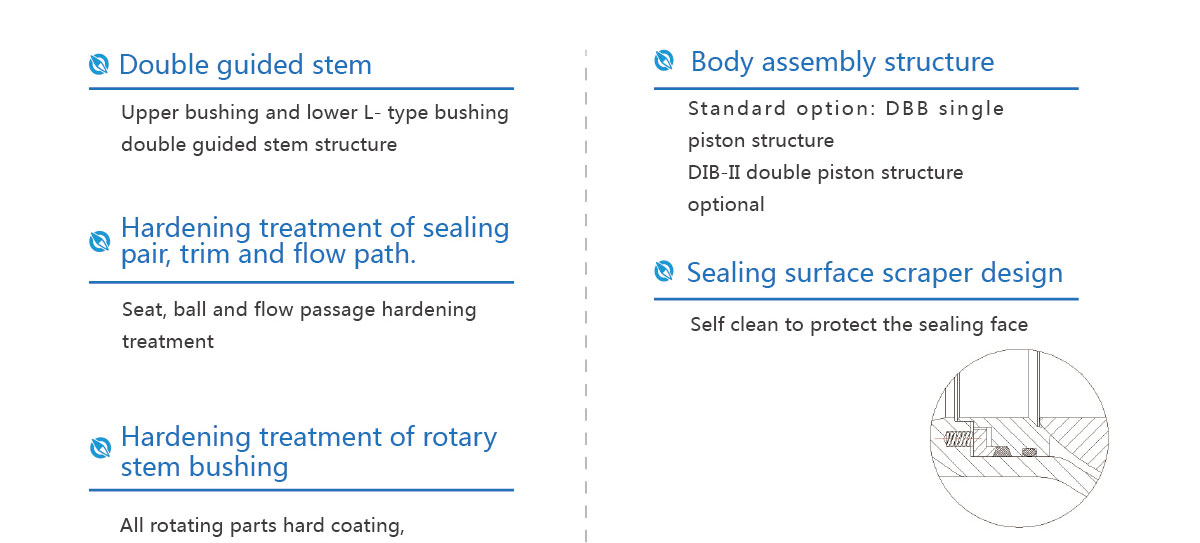

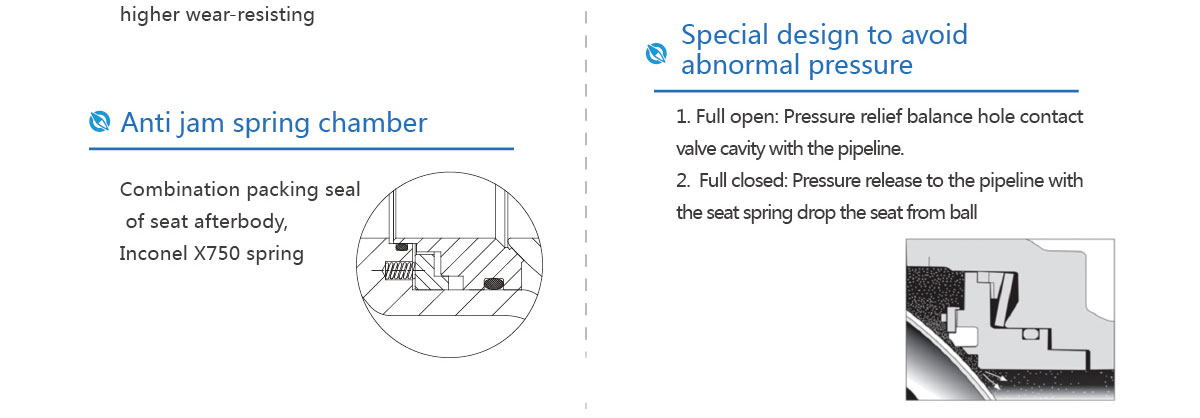

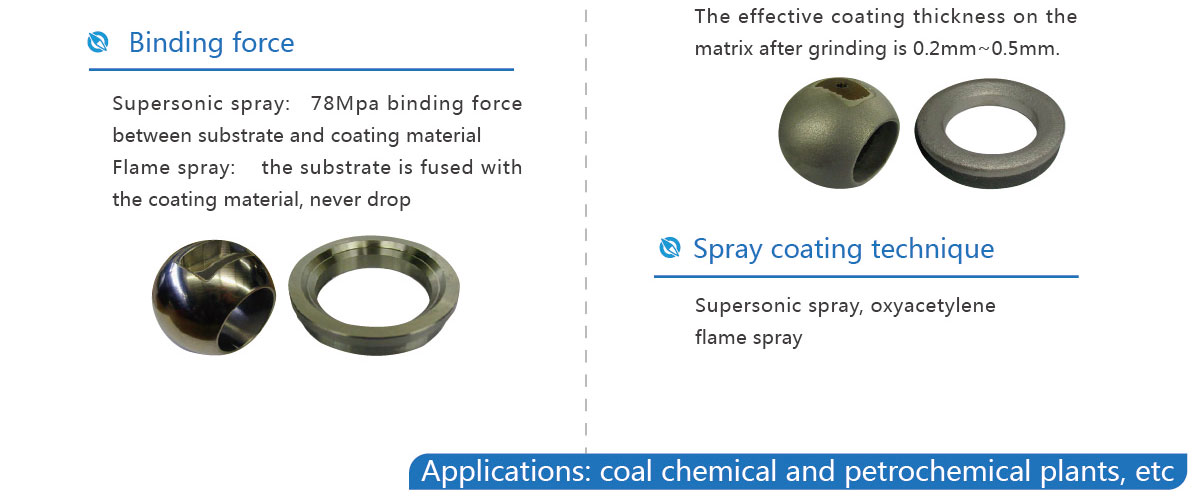

Ball and seat are hardened: advanced supersonic spraying or thermal spray welding technology, for the user's different working conditions, spray welding cobalt-based alloy, nickel-based alloy or spraying tungsten carbide, chromium carbide, etc. on the surface of the ball and seat, the special hardening treatment, wear resistance is extremely high, can be applied to most of the harsh working conditions

High temperature anti-expansion: high temperature conditions due to thermal expansion and easy to cause the expansion of the ball and seat, resulting in the valve can not open. The ball valve adopts a spring-loaded special sealing structure, the thermal expansion of parts at high temperatures can be absorbed by the spring, so it can ensure that the ball valve continues to be flexible in the high-temperature state to open.

Excellent sealing performance: the unique ball grinding process is adopted, and through the rotation of the ball and the grinding apparatus in different directions in space, the ball surface achieves extremely high roundness and smoothness, and the sealing performance of the valve completely meets or exceeds the standard requirements.

Intrinsic fireproof structure, natural anti-static structure.

Anti-blow-out design of the valve stem.

Allowable leakage: bubble level leakage in accordance with the requirements of API598.

And pipeline connection with RF, RJ, FM and other flange type and SW, BW welding type.

Flange distance in line with GB/T12221/ASME B16.10; flange standard in line with HG/T20592 or ASME B16.5.

Puyang Zhong Hui New Energy Technology Co., Ltd, 200,000 tons per year of naphtha benzene hydrogenation project

Liaoning Baolai Chemical Co., 1 million tons of ethylene plant fire water project

Panjin North Asphalt Fuel Co., Ltd, low carbon hydrocarbon hydrogenation plant and plant-wide condensate pipeline network project

Usu Yuxi Petrochemical Company Limited, Usu Yuxi Safety Hazard Management Project

China National Offshore Oil Industrial Self-Control (Tianjin) Co., Oil and Gas Storage Phase I Expansion of LPG Spherical Tank and Modification

TECHNICAL PARAMETERS

| Nominal Size | DN15~DN400 |

| Pressure Rating | PN/160/250/CL900(PN150)/1500(PN260)/2500(PN420) |

| Operateing Temperature | -46℃~538℃ |

| Characteristics | Quickly open |

| Rangeability | / |

| Seat Leakage Class | Zero Leakage |

| Body Material | WCB、CF8、CF8M etc. |

| Trim Material | 304+Ni60/304+WC/316+Ni60/316+WC etc. |

| Seal Material | PTFE, Flexible graphite |

Nominal diameter: DN15/20/25/32/40/50/65/80/100/125/150/200/250/300 /350/400/450/500/600/700/800

Pressure rating: ANSI CL150/300/600; DIN PN16/25/40/63/100

Material of valve body and upper valve cover: WCB, WCC, WC6, WC9, LCB, LCC, CF8, CF8M, CF3, CF3M, etc.

Structure form: floating type; fixed type.

Packing type: flexible graphite (use temperature -196℃~+593℃).

Flow characteristics: quick-open (Q).

Allowable leakage: in accordance with the requirements of API6D, API 598.

Headquarter Add.: SUPCON Park, No.309 Liuhe Road, Binjiang District, Hangzhou, 310053, China.

Tel.: +86 571 8111 9774

Fax: +86 571 8111 9737

E-mail: [email protected]