SFE900 electromagnetic flowmeter is a product with high precision and high reliability after continuous upgrading and improvement. The flowmeter has reached the domestic advanced level in terms of excitation technology, lining technology and intelligent technology

Product Description

The electromagnetic flowmeter can handle critical flow applications to enhance accuracy, reduce system maintenance, and meet the demands of challenging liquid conditions. This volumetric flowmeter has no moving parts, making it ideal for wastewater applications or any dirty liquids that are conductive or water-based.

Utilizing an integral welding structure, the device ensures excellent sealing performance.

The structure with no moving components internally is straightforward and dependable, leading to minimal pressure loss.

The instrument demonstrates quick responsiveness, providing an output signal that linearly corresponds to the flow rate with a broad measurement range.

Utilizing low-frequency square wave excitation, the device exhibits excellent anti-interference capabilities and stable zero-point performance.

With excitation fault alarm function and electrode fault data judgment function.

The converter has good interchangeability, and accuracy measurement can be achieved without recalibrating.

Featuring parameter setting storage function, it can restore the original settings with a single key press.

The installation requirements are simple. The front straight pipe section is 5D or above, and the rear straight pipe section is greater than 3D (D is the inner diameter of the instrument).

Equipped with an empty pipe alarm function to prevent measurement errors caused by flow meter data fluctuations due to empty pipe interference.

Only the lining and electrode of the instrument are in contact with the measured medium, so the requirements of corrosion and wear resistance can be achieved on more occasions.

High measurement accuracy with minimal interference from factors such as flow velocity distribution, pressure, temperature, etc., and it supports bidirectional measurements.

The sensor has low power consumption, with the total power consumption of the complete instrument being less than 10VA (DC 10W), irrespective of the sensor size.

Featuring a display angle configuration function, it supports display angles set at 0°, +90°, 180°, and -90°.

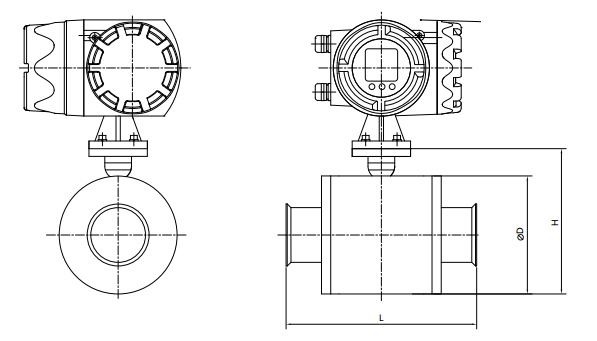

The L-shaped meter head design facilitates installation in process industries, as well as parameter observation and data reading.

Magnetic Field Generation: Two electromagnetic coils generate a magnetic field perpendicular to the flow of the conductive fluid inside the meter tube.

Induced Voltage: As the conductive fluid moves through the magnetic field, it acts as a conductor, inducing a voltage.

Electrode Detection: Two electrodes placed on the inner walls of the flow tube detect the induced voltage, which is proportional to the fluid velocity.

Flow Rate Calculation: The induced voltage () is given by the formula:

Where:

Since the pipe’s cross-sectional area is known, the volumetric flow rate () can be calculated:

Where is the cross-sectional area of the pipe.

= Induced voltage (V)

= Magnetic field strength (T)

= Fluid velocity (m/s)

= Distance between electrodes (m)

Water and wastewater treatment

Chemical and pharmaceutical industries

Food and beverage processing

Slurry and pulp flow in mining and paper industries

Parameter | Integrated Type | Remote Type |

Measuring Range | (0.1~12)m/s, recommended use range is between (0.3~10)m/s | |

Flow Display | LCD display with comprehensive information, screen text angle configurable in the menu to avoid the need for adjusting the meter head angle due to installation issues | |

Diameter(mm) | Please refer to the instrument category description for more details | |

Accuracy | (0.5~10)m/s: ±0.5%(±0.3%, ±0.2% optional ); (0.3~0.5)m/s: ±0.5% | |

Repeatability | 0.25%/0.1%(according to corresponding accuracy requirements) | |

Lining Material | Chloroprene rubber, polyurethane rubber, PTFE, PFA, FEP | |

Electrode Material | 316L, Hastelloy (HB, HC), tantalum (Ta), titanium (Ti), tungsten carbide (WC), platinum-iridium alloy | |

Grounding | Grounding electrode or ring | |

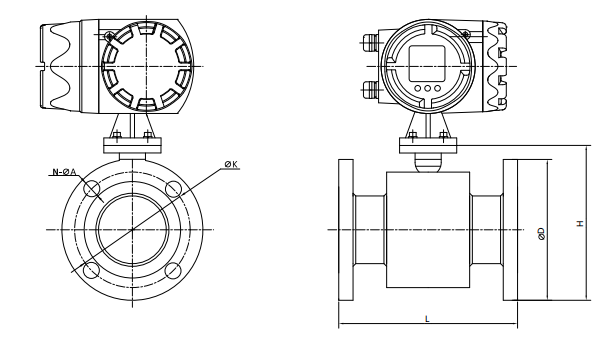

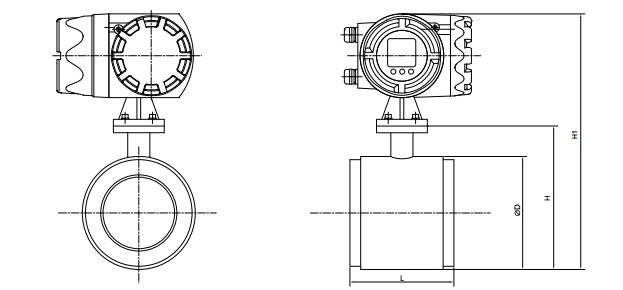

Connection Mode | Flange connection, compact, plug-in type, threaded type, clamp type | |

Flange Connection | Applicable standards: GB, HG, JB, ANSI, DIN, JIS | |

Pressure Rating | 0.25MPa,0.6MPa,1.0MPa,1.6MPa,2.5MPa,4.0MPa,6.4MPa, other pressure ratings customized | |

Medium | Conductive liquid | |

Medium Conductivity | ≥ 5μS /cm | |

IP Degree | IP65/IP67/IP68( applicable to remote type) | |

Exciting Method | Low frequency rectangular wave excitation | |

Measurement Direction | Positive / negative / bidirectional directions | |

Output Signal | Current, pulse, frequency | |

Communication | RS-485(Modbus-RTU、Modbus-ASCII)、HART | |

Cable Entry | M20x1.5 | |

Alarm | Empty pipe alarm, excitation alarm, zero alarm, over-range alarm | |

Power Supply Mode | 220VAC、24VDC | |

Display Language | Chinese/English | |

Ambient Temperature | (-20~55)℃ | (-40~60)℃, converter temperature (-20~55)℃ |

Ambient Humidity | (5~90)% | |

Storage Temperature | (-40~65)℃ | |

Explosion Proof Sign | Ex dbib mb ll C T6 Gb | |

Product Execution Standard | JB/T9248-2015 | |

Diameter(mm) | DN(25~200) |

Electrode Material | 316L, Hastelloy (HB, HC), tantalum (Ta), titanium (Ti), tungsten carbide (WC), platinum-iridium alloy |

Lining Material | FEP |

Process Temperature | Limited by the temperature resistance of lining materials, reference 7.2 |

Housing Material | Carbon steel(can customize the stainless steel housing) |

IP Degree | IP65、IP67、IP68 |

Connection | Compact Type. Applied in corresponding pressure of the flange with all kinds of standard(such as GB, HG) |

Multi-electrode structure | For insulated pipelines, it is recommended to use a three(four) electrode structure, where one (two) grounding electrode(s) ensures that the measured medium and the sensor body maintain the same potential. This setup allows for flowmeter installation on insulated pipelines without the need for a grounding ring. |

Limit Pressure | Reference table 3 flange type sensor |

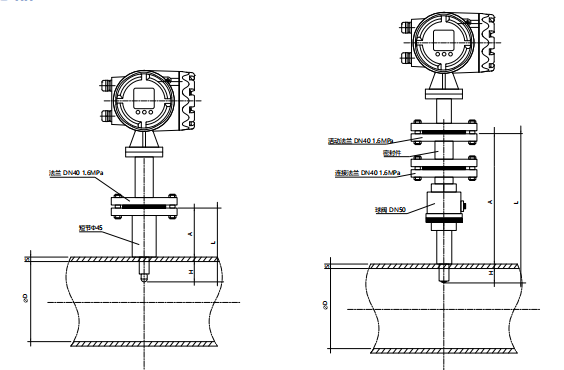

Diameter (mm) | ≤ DN3000 |

Electrode Material | SS316L |

Lining Material | PTFE |

Process Temperature | (0~120)℃ |

IP Degree | IP65、IP67、IP68 |

Limit Pressure | 1.6MPa |

Accuracy | 1.5%、2.5% |

Diameter (mm) | DN(5~80) |

Electrode Material | 316L, Hastelloy (HB, HC), tantalum (Ta), titanium (Ti), tungsten carbide (WC), platinum-iridium alloy |

Lining Material | FEP, PFA |

Process Temperature | Limited by the temperature resistance of lining materials, reference 7.2 |

IP Degree | IP65、IP67、IP68 |

Connection | Tread type |

Limit Pressure | 1.0MPa |

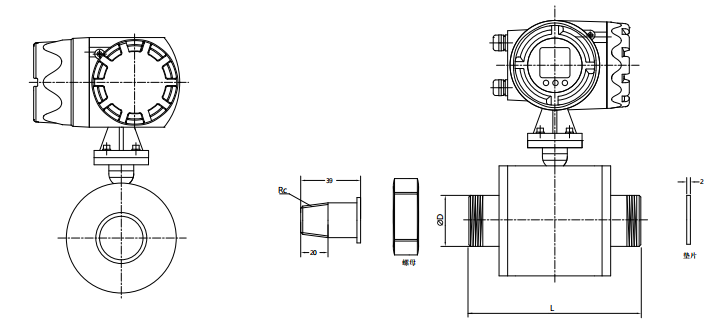

Diameter (mm) | DN(15~80) |

Electrode Material | 316L, Hastelloy (HB, HC), tantalum (Ta), titanium (Ti), tungsten carbide (WC), platinum-iridium alloy |

Lining Material | PTFE, FEP, PFA |

Housing Material | SS304 (316, 316L optional) |

Clamp connector | 316L, clamp standard DIN32676 or ISO2825 |

Process Temperature | Limited by the temperature resistance of lining materials, reference 7.2 |

IP Degree | IP65、IP67、IP68 |

Connection | Clamp-Type |

Limit Pressure | 1.0MPa |

Headquarter Add.: SUPCON Park, No.309 Liuhe Road, Binjiang District, Hangzhou, 310053, China.

Tel.: +86 571 8111 9774

Fax: +86 571 8111 9737

E-mail: [email protected]