It features a robust design that resists mechanical vibrations, impacts, and contamination. With no moving parts and minimal wear, it requires no mechanical maintenance. The meter provides low pressure loss, high accuracy, easy installation, and stable performance. Its sensor and signal converter can be matched freely.

Product Description

The vortex flowmeter, featuring the smallest strut in the industry, offers high sensitivity and outstanding performance. It is suitable for measuring steam, as well as a variety of liquids and gases.

Leak-proof design

One-button zeroing function

Vibration and interference-resistant design

· Patented “non-flow interrupting sensor head removal” capable of measuring up to 420°C

· Resistant to wear and contamination, maintenance-free, long lifespan, explosion-proof, and suitable for harsh environments

· On-site LCD display with instantaneous flow, cumulative total, percentage, and frequency readings

· Measurement results are unaffected by velocity distribution, fluid pressure, temperature, density, or viscosity

· Bluetooth-enabled for short-range wireless parameter configuration (within 20 meters) for easy field operation

A Vortex Flowmeter operates based on the Von Kármán Vortex Street principle. When a fluid flows past a bluff body (a non-streamlined object) placed in the flow path, alternating vortices are shed downstream. The frequency of these vortices is directly proportional to the flow velocity of the fluid.

Bluff Body Formation: A specially designed bluff body is placed in the flow path inside the meter.

Vortex Shedding: As the fluid moves past the bluff body, vortices are created alternately on both sides.

Detection Mechanism: A sensor, typically a piezoelectric or capacitive element, detects the pressure fluctuations caused by the vortex shedding.

Frequency Measurement: The frequency of vortex shedding is measured and is directly proportional to the flow rate.

Flow Rate Calculation: The meter converts the vortex frequency into volumetric or mass flow rate using calibration factors.

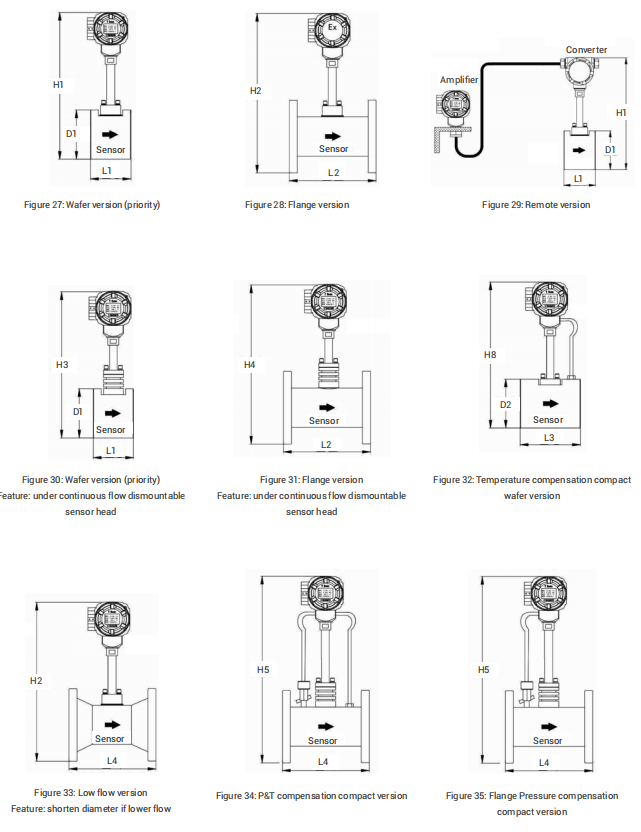

| Caliber DN | H1a | H1b | H2a | H2b | H3a | H3b | H4a | H4b | H5 | H8 | D1 | D2 | L1 | L2 | L3 | |

| 15 | 350 | 520 | / | / | / | / | 95 | 50 | 200 | / | ||||||

| 20 | / | / | 355 | 525 | / | / | / | / | / | / | 100 | / | 50 | 200 | / | / |

| 25 | / | / | 360 | 530 | / | / | / | / | 605 | 100 | 60 | 50 | 200 | / | 275 | |

| 32 | / | / | 372 | 542 | / | / | / | / | 618 | / | 105 | 65 | 54 | 200 | / | 275 |

| 40 | 355 | 525 | 388 | 558 | 457 | 627 | 485 | 655 | 655 | 567 | 92 | 92 | 78 | 200 | 112 | 275 |

| 50 | 358 | 528 | 400 | 570 | 464 | 634 | 498 | 668 | 668 | 574 | 98 | 98 | 78 | 200 | 112 | 275 |

| 65 | 373 | 543 | 422 | 592 | 475 | 645 | 515 | 685 | 685 | 585 | 110 | 110 | 78 | 200 | 112 | 275 |

| 00 | 396 | 566 | 435 | 605 | 499 | 659 | 530 | 700 | 700 | 609 | 134 | 134 | 90 | 225 | 112 | 300 |

| 100 | 419 | 589 | 454 | 624 | 523 | 693 | 551 | 721 | 721 | 633 | 158 | 158 | 78 | 250 | 112 | 350 |

| 125 | 440 | 610 | 484 | 654 | 540 | 710 | 579 | 749 | 749 | 650 | 175 | 175 | 78 | 275 | 112 | 375 |

| 150 | 465 | 635 | 513 | 683 | 565 | 735 | 611 | 781 | 781 | 675 | 200 | 200 | 100 | 300 | 140 | 400 |

| 200 | 515 | 685 | 567 | 737 | 615 | 785 | 662 | 832 | 832 | 725 | 250 | 250 | 120 | 350 | 160 | 450 |

| 250 | 565 | 735 | 620 | 790 | 665 | 835 | 715 | 885 | 885 | 775 | 300 | 300 | 140 | 400 | 180 | 500 |

| 300 | 615 | 785 | 670 | 840 | 715 | 885 | 765 | 935 | 935 | 825 | 350 | 350 | 160 | 450 | 200 | 550 |

| 350 | 665 | 835 | 725 | 895 | 765 | 935 | 820 | 990 | 990 | 875 | 400 | 400 | 165 | 500 | 220 | 600 |

| 400 | 715 | 885 | 781 | 951 | 815 | 985 | 875 | 1045 | 1045 | 925 | 450 | 450 | 185 | 550 | 240 | 650 |

| 450 | 765 | 935 | 830 | 1000 | 865 | 1035 | 925 | 1095 | 1095 | 975 | 500 | 500 | 205 | 600 | 260 | 700 |

| 500 | 815 | 985 | 885 | 1055 | 915 | 1085 | 978 | 1148 | 1148 | 1025 | 550 | 550 | 225 | 650 | 280 | 750 |

| Note:Thisproduct has two kinds of struts with diferent lengths,so the height of some models are dividedinto a and b. | ||||||||||||||||

TECHNICAL PARAMETERS

| LUGB | ||

| Medium | Liquid,gas (including natural gas),steam (saturated steam,superheated steam) | |

| Nominal diameter | LUGB pipe type | DN(15~500) |

| Accuracy class | LUGB pipetype | 1.0,1.5(class 0.5 supplied by agreement) |

| Flow range | See table 2,table 3,table 4,table 5 and table 6 | |

| Nominal pressure | LUGB Pipe type flange clamping | DN(15~500)(preferred pressure class PN2.5MPa) |

| LUGB Pipe type flange connection | DN(15~80)(pre ferred pressure class PN2.5MPa) | |

| DN(100~200)(preferred pressure class PN1.6MPa) | ||

| DN(250~500)(preferred pressure class PN1.0MPa) | ||

| Medium temperature | LUGB pipe type | (-40~+150)℃,(-40~+260)℃,(-40~+320)℃ (-40~+420)℃,(DN40~DN300℃ |

| Ambient condition | Ambient temperature | (-20~+60)℃(Normal) (-20~+40)℃ (Explosion proof) |

| Relative humidity | (5~95)%RH | |

| Atmospheric pressure | (86~106)kPa | |

| Electrical interface | M20×1.5 internal thread (other types of joints can be supplied by agreement) | |

| Protection level | IP65(IP68 supplied by agreement) | |

| Explosion proof grade | Intrinsically safe and flameproof | |

| Body material | Stainless steel (other materials supplied by agreement) | |

| Pressure loss | △P≤1.2 p₀V²(Unit:△P..Pa,po-kg/m³,v-…m/s) | |

| Calibration method | The company adopts the downstream side pressure measurement for the flowmeter factory calibration | |

| Note:special fange is used for clamping vortex street,and matchingflangehas been included in thefactory (comply wit national standard GB/T9119- 2010;ANSIASME/DIN/JIS/KS). The prefered pressure levelis default.Other pressure levels or flange standards can be suplied by agreement. | ||

Headquarter Add.: SUPCON Park, No.309 Liuhe Road, Binjiang District, Hangzhou, 310053, China.

Tel.: +86 571 8111 9774

Fax: +86 571 8111 9737

E-mail: [email protected]